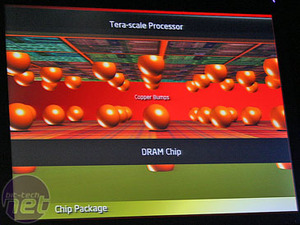

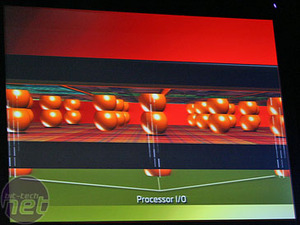

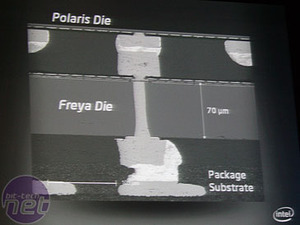

Then little copper balls are made on top of the channel which is then matched to similar copper balls on the underside of the Terascale (Polaris) die. The processor I/O then passes through, either out of the chip or accesses the memory underneath.

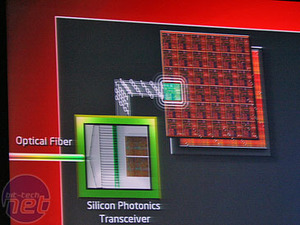

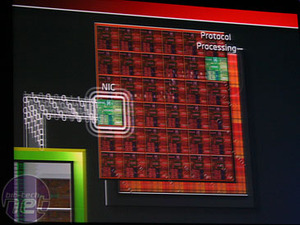

Because we are approaching the limits of electrical data speed quickly (due to the fact that copper only has a certain level of conductance, resistance and capacitance), optical interconnects are determined to be the future, as it'll unlock more bandwidth.

If an electrical signal is sent down a wire and then another is sent down the same wire before the effect of the previous signal (capacitance) has died, the second signal will be corrupted. You can reduce this by lowering the voltage, but that means the wire resistance has to be as low as possible.

In comparison, optical interconnects don’t suffer the same limitation because, as soon as the laser is fired, the only limitation is the speed of light. Intel has already designed the silicon laser with integrated pump, so while copper interconnects are still cheaper, it’s only a matter of time before the price vs. performance ratio is favours a move to optical interconnects.

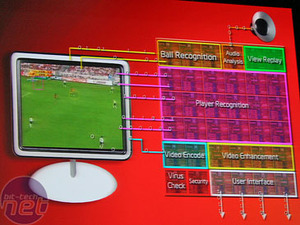

Intel showed off a potential application of its Terascale processor, using it to calculate football highlights. It splits the array to separate player and ball recognition, video encoding and enhancements, as well as audio analysis. This allows the chip to make highlights of your favourite sporting events (in this case football) for viewing at a later date.

Why Intel thinks you need 80 cores to complete this task is interesting though, because CyberLink has previously showed bit-tech its MagicSports software, which allows you to do exactly the same thing today. However, we guess that Intel's Terascale chip will be able to complete the task in much less time.

Because we are approaching the limits of electrical data speed quickly (due to the fact that copper only has a certain level of conductance, resistance and capacitance), optical interconnects are determined to be the future, as it'll unlock more bandwidth.

If an electrical signal is sent down a wire and then another is sent down the same wire before the effect of the previous signal (capacitance) has died, the second signal will be corrupted. You can reduce this by lowering the voltage, but that means the wire resistance has to be as low as possible.

In comparison, optical interconnects don’t suffer the same limitation because, as soon as the laser is fired, the only limitation is the speed of light. Intel has already designed the silicon laser with integrated pump, so while copper interconnects are still cheaper, it’s only a matter of time before the price vs. performance ratio is favours a move to optical interconnects.

Intel showed off a potential application of its Terascale processor, using it to calculate football highlights. It splits the array to separate player and ball recognition, video encoding and enhancements, as well as audio analysis. This allows the chip to make highlights of your favourite sporting events (in this case football) for viewing at a later date.

Why Intel thinks you need 80 cores to complete this task is interesting though, because CyberLink has previously showed bit-tech its MagicSports software, which allows you to do exactly the same thing today. However, we guess that Intel's Terascale chip will be able to complete the task in much less time.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.